The laboratory is known as the "heart" of the factory. For textile printing and dyeing factories, sampling is the first step in establishing cooperation with customers, and it is also an important step in improving the dyeing rate and production efficiency. Nowadays, Meixinda's "heart" has been equipped with "digital" wings, increasing efficiency by about 30%.

The production of a color starts from the raw fabric and generally requires more than ten processes, including pre-treatment, color matching, dyeing, and finishing. The slight differences in each operation process can accumulate to cause significant color differences in the finished product. In Meixinda's production workshop of hundreds of thousands of square meters, batches of colorful finished fabrics are constantly emerging. Behind the monthly printing and dyeing of fabrics reaching millions of meters is the "digital economy" of enterprise transformation and upgrading.

1

Intelligent algorithm empowerment

Let the sample add "number" to move forward

From receiving orders, color matching, dripping, making samples... and finally confirming with the customer. The single color matching time has been reduced from 5 minutes to 30 seconds, and the sampling accuracy has been improved from 65% to over 95%... These advantages have been concentrated in the Meixinda Intelligent Dyeing System.

In the past, color matching masters had to repeatedly observe customer samples, write down the first party based on experience, and then modify the formula through repeated sampling. Now, sample makers only need to receive order requirements and standard samples on the AIDyeing Cloud platform, and obtain smart formulas with one click. This not only achieves automatic droplet sampling of formulas, but also breaks down the color communication barriers between the laboratory and business and production departments, improving communication efficiency and ensuring accuracy.

With the assistance of AIDyeing, online digital management of the entire sampling process has been achieved, and the sampling results have been quantified into various data parameters. ABC samples can be automatically sent to the demand department. At the same time, the system tracks the sampling process in real-time, automatically calculates the performance and rotation of samplers, and improves the transparency and intelligence of laboratory sampling and management.

"Currently, for Meixinda, the most important thing is to focus on products, accelerate product research and development capabilities and speed. With the help of the AIDyeing platform, we can improve our order taking and production capabilities more quickly, so that we have the strength to compete in the market, customers, and run faster." said the General Manager of Meixinda's overflow manufacturing department.

When talking about the achievements brought by the AIDyeing Cloud Platform, the sampling supervisor of Meixinda Laboratory said, "Since using this system last year, the overall efficiency has improved a lot. Previously, we could only rely on manual experience for color matching and sampling, but now we rely on the system to automatically produce and adjust colors. On average, we can dye images in 1-3 rounds, which is faster and more accurate than manual labor." It is reported that it used to take about 2-3 years to cultivate a qualified sampling master. Now, Newcomers only need a few weeks to learn how to use intelligent methods and color correction.

In addition, there will be two electronic screens in the Meixinda laboratory. One is the sampling progress screen, which clearly displays every link from business order acceptance, sampling status, customer confirmation, color evaluation, etc. on the electronic screen; One is the sample statistics screen, which displays the success rate of staining in the laboratory, the sample color, sample efficiency, and the proportion of time spent by each sample maker, providing a clear overview of the actual sample making process.

智染通-打樣數(shù)據(jù)看板概覽

2

Upgrade of production data management

From "owned for me" to "used for me"

Zhejiang Meixinda, which started from a small printing and dyeing factory in 1993, is now a group company with tens of thousands of employees. Its textile printing and dyeing technology company has many popular first tier brands and is also a designated fabric supplier for China's astronaut specific aviation suits.

The report of the 20th National Congress proposes to build a modern industrial system, promote new industrialization, and accelerate the construction of a strong manufacturing country and a digital China. The person in charge of the Information Data Department of Meixinda Printing and Dyeing Technology stated, "The intelligent dyeing cloud platform is connected with the ERP system and production system data, achieving automatic order flow, automated connection of various dyeing processes, and smoother collaboration between departments. The next step is to continue to accelerate the integration and application of Meixinda's information system and the digital and intelligent upgrading of production, creating a smart printing and dyeing technology brain."

In fact, even before the digital upgrade, Meixinda had already accumulated and saved a large amount of color data. However, due to the lack of color digitization, a large amount of color data can only be recorded on paper and stored in color samples. The difficulty of searching has made the large amount of color data not truly utilized.

The core of digital transformation lies in data access and intelligent applications. The Smart Dyeing Cloud Platform covers core businesses such as order management, intelligent sourcing, intelligent color correction, blended color matching and correction, intelligent storage of color samples, production of one-time dyeing formulas, production color correction, color monitoring and warning during the production process, and conducts full lifecycle management of factory colors. At the same time, the platform manages color data and formulas uniformly in the cloud, achieving cross factory, multi laboratory, and multi workshop data interconnection and sharing of technical experience. By establishing the Meixinda core dyeing technology database and cooperating with the AIDyeing system, production data can be truly utilized Mengke General Manager Liu Xinbing introduced it.

3

Transformation password:

Accelerate the construction of a smart printing and dyeing ecological factory

Currently, the trend of digitalization has led more and more manufacturing enterprises to join the wave of digital transformation. However, due to the varying levels of enterprise development and the diversification of transformation needs, the implementation of digital factories has become even more difficult. So, how can we overcome the traditional printing and dyeing dilemma and make digital factories efficiently implemented? Becoming a challenge for major factories.

Upgrading from "traditional printing and dyeing" to "smart factory", Meixinda has found the right way to open it.

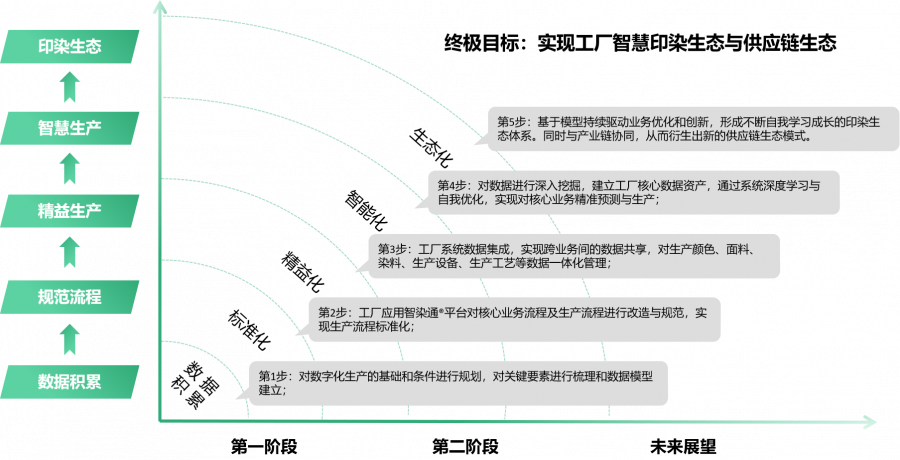

According to Meixinda's digital strategy deployment, the AIDyeing cloud platform gradually extends from Meixinda's

laboratory to intelligent color library management and intelligent production management, creating a tailored digital

transformation path for Meixinda's own development

Mr. Liu stated that, We not only provide a professional platform for Meixinda, but also dispatch professional technical personnel to provide system implementation services on site based on Meixinda's on-site needs, ensuring that products can truly realize their value and be well applied. Moreover, the platform will automatically record production data, accumulate each production experience, and apply each experience to the next color production, forming a system for automatic accumulation and self-learning "The automatically corrected ecological cycle provides real-time optimal production solutions."

Mr. Liu stated that, We not only provide a professional platform for Meixinda, but also dispatch professional technical personnel to provide system implementation services on site based on Meixinda's on-site needs, ensuring that products can truly realize their value and be well applied. Moreover, the platform will automatically record production data, accumulate each production experience, and apply each experience to the next color production, forming a system for automatic accumulation and self-learning "The automatically corrected ecological cycle provides real-time optimal production solutions."

Back